HANYU Boiler (Henan) Co., Ltd. is a star enterprise in the industrial boiler industry with a long production history, more production varieties and reliable quality. There are five enterprises under HANYU Boiler (Henan) Co., Ltd.: Shandong Sitong Thermal Equipment Co., Ltd; HANYU Boiler (Henan) Co., Ltd. can provide users with boiler research and development, manufacturing, installation, energy-saving transformation, maintenance of one-stop service.

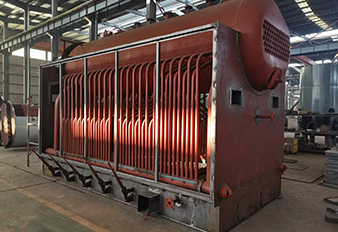

Production products are: steam boilers, hot water boilers, organic heat carrier furnace three categories: WNS and SZS oil-fired gas boilers, SHX circulating fluidized bed boilers, DHL Angle Tube Chain Grate Boilers, SZL Chain Grate Boilers, SZS coal-water slurry boilers, YYW and YYL oil-fired gas organic heat carrier furnaces, special-fueled boilers (biomass boilers, electric boilers) and more than 300 varieties of specifications.

Our products have been tested by internationally renowned certification bodies to ensure that we provide the best quality and service to every customer

Products: steam boilers, hot water boilers,and son on more than 300 varieties of specifications.

RMB 80 million yuan

Building area of 50,000 square meters

Maximum plate rolling capacity of 50 mm

HANYU Boiler (Henan) Co., Ltd. took the lead in passing the ISO9001:2000 international quality system certification and established a scientific, strict and effective quality assurance system. It has established a quality manual and a large number of program documents and working documents for design and development control, product manufacturing and quality control, material and material procurement control, sales and service control, etc. It has set up internal control standards which are higher than the national standards.

HANYU Boiler (Henan) Co., Ltd. has total assets of RMB 80 million yuan, covers an area of 80,000 square meters, building area of 50,000 square meters, production workshop area of 30,000 square meters, workshop with maximum lifting capacity of 50 tons, maximum plate rolling capacity of 50 mm plate thickness, maximum cutting diameter of 4,000 mm, and annual production capacity of 6,000 steam tons.

We always insist on the progress of technology and adopt advanced production technology and equipment. Mainly: 80 mm plate thickness coiler, 4000 mm large diameter lathe, large computerized membrane wall production line, flat steel finishing automated production line, horizontal mechanical pipe screen bender, pipe polishing and descaling production line, large CNC automatic cutting machine, automatic submerged arc welding machine, saddle automatic cutting machine and automatic welding machine, argon arc automatic welding, CO2 gas shielded welding, boiler tube end all-position automatic welding, corrugated furnace chamber Spinning machine, threaded pipe machine tool, thermal oil coiler, milling machine, high-precision testing equipment, etc., as well as a fully enclosed hydraulic test center and boiler performance test center and 200 square meters of X-ray flaw detection burst room 2, etc..

Our products have passed the CE certification of EU, Lloyd's Register certification and ASME certification of USA, and have been exported to more than one hundred countries and regions: Russia, Kazakhstan, Congo, Lesotho, Kenya, Costa Rica, Nigeria, South Africa, Venezuela, Ethiopia, Sri Lanka, Indonesia, the Philippines, Thailand, Vietnam, Cambodia and so on, and the exported products are favored by the local users.